Operations management is a vital aspect of any organization that deals with the production and delivery of goods and services. Effective operations management requires careful planning, execution, and monitoring of various activities and resources involved in the production process. In this blog post, we will explore some of the key concepts in operations management, including supply chain management, inventory management, production process, quality control, resource allocation, analytics and reporting, process optimization, business operations, and industrial manufacturing.

Supply Chain Management:

Supply chain management involves the coordination and management of all activities involved in the production and delivery of goods and services, including sourcing, procurement, manufacturing, logistics, and distribution. Effective supply chain management ensures that products are delivered to customers on time, at the right quality, and at the lowest possible cost.

Inventory Management:

Inventory management involves the management of inventory levels and processes, including inventory planning, ordering, tracking, and control. Effective inventory management ensures that the right amount of inventory is available at the right time, preventing stockouts and excess inventory that can lead to waste and increased costs.

Production Process:

The production process involves the creation and delivery of goods and services, from design to delivery. Effective production processes require careful planning, execution, and monitoring to ensure that the products are manufactured efficiently, at the right quality, and at the lowest possible cost.

Quality Control:

Quality control involves the monitoring and control of processes to ensure that products meet the required quality standards. Effective quality control processes include regular inspections, audits, and testing to identify defects and ensure that products meet customer expectations.

Resource Allocation:

Resource allocation involves the management of resources, including people, materials, and equipment, to ensure that they are utilized efficiently and effectively. Effective resource allocation helps to maximize productivity, reduce waste, and minimize costs.

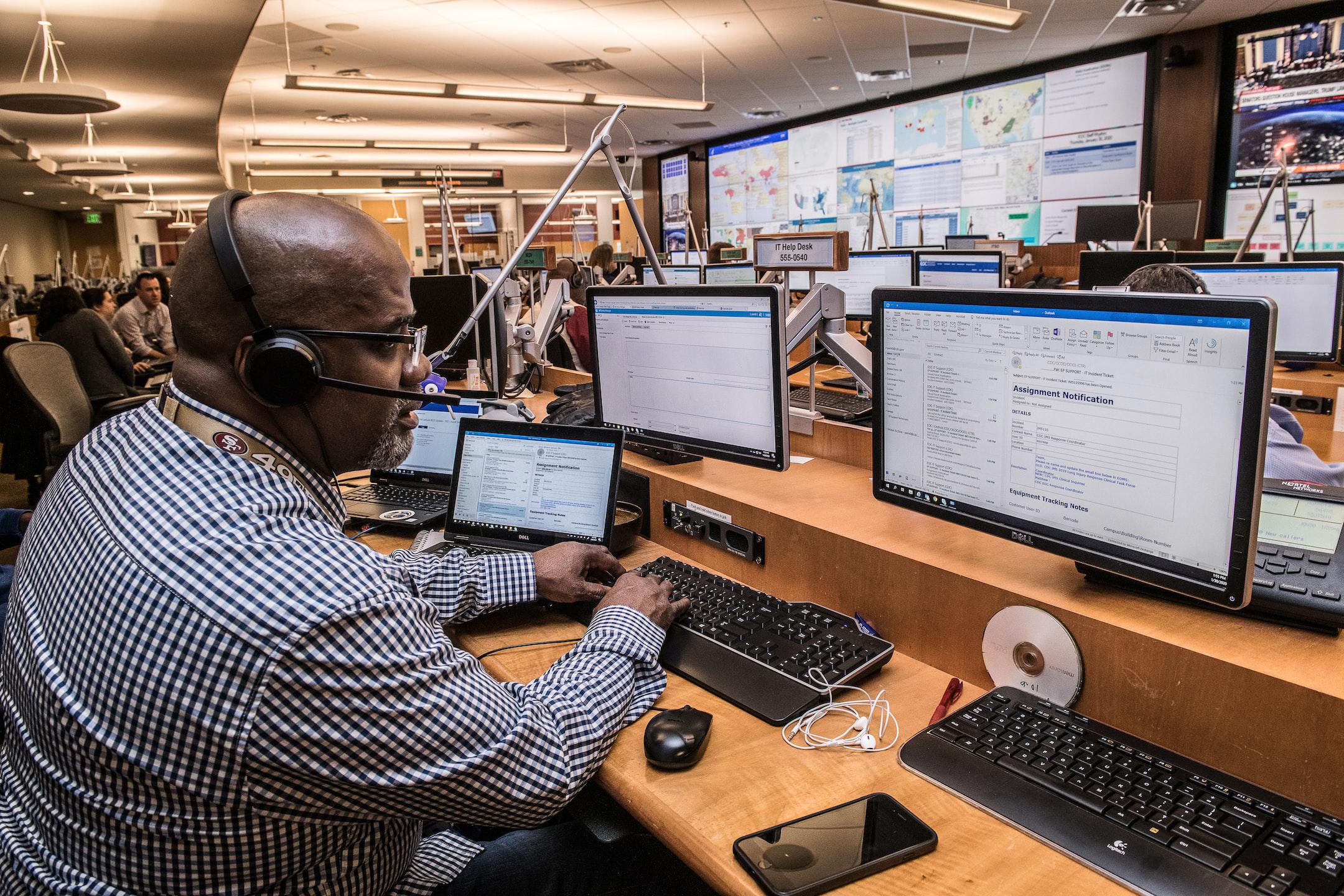

Analytics and Reporting:

Analytics and reporting involve the collection, analysis, and reporting of data related to operational performance. Effective analytics and reporting provide insights into operational efficiency, identify areas for improvement, and support informed decision-making.

Process Optimization:

Process optimization involves the identification, analysis, and improvement of operational processes to increase efficiency, reduce waste, and improve quality. Effective process optimization requires a systematic approach, including process mapping, data analysis, and continuous improvement.

Business Operations:

Business operations involve the management of all activities involved in running a business, including marketing, sales, finance, human resources, and information technology. Effective business operations require a coordinated approach, ensuring that all functions work together to achieve the organization's goals.

Industrial Manufacturing:

Industrial manufacturing involves the production of goods using advanced manufacturing technologies, including automation, robotics, and artificial intelligence. Effective industrial manufacturing requires careful planning, execution, and monitoring to ensure that products are manufactured efficiently, at the right quality, and at the lowest possible cost.

In conclusion, effective operations management requires a coordinated approach, ensuring that all activities and resources involved in the production and delivery of goods and services are managed efficiently and effectively. By focusing on key concepts such as supply chain management, inventory management, production process, quality control, resource allocation, analytics and reporting, process optimization, business operations, and industrial manufacturing, organizations can improve their operational efficiency, reduce costs, and increase customer satisfaction.